Specialist subcontractor TMA Group brings you expertise, skills and rapid service in the field of precision industrial sheet metal working, cutting and metal processing. To ensure customer satisfaction, the TMA Group is constantly improving its quality policy.

The TMA Group is certified to ISO 9001:2015

ISO 9001 certified since 2021, the TMA Group works daily to meet its customers’ requirements and strives to exceed their expectations whenever it can. ISO 9001 encompasses a number of quality management principles, including a strong customer focus, motivation and commitment at company level, a process-based approach and continual improvement.

Holding this certification is a guarantee of quality, which reinforces the company’s approach to quality and customer satisfaction whilst ensuring the work of each and every employee is properly valued. The TMA Group is now working to obtain other certifications that will guarantee the quality of its know-how and skills.

Powerful tools for checking the compliance of metal parts

The compliance of the metal parts produced is checked using specific, latest generation tools. With equipment such as a handheld CMM, a 3D scanner for complex parts and a handheld probe CMM, the TMA Group possesses a comprehensive range of high-performance measuring instruments. Digitising parts, measuring volumes, checking geometrical tolerances and matching with CAD designs are some of the checks these tools are used for. The precision of these instruments to within ± 3 μm ensures stringent controls.

Other more traditional tools are also used to check the compliance of your parts: vernier callipers, depth gauges, micrometers, flatness rulers, protractors, marking gauges, etc.

Regular investments mean we are able to rely on ever more effective and precise tools to ensure the compliance of large runs of complex parts.

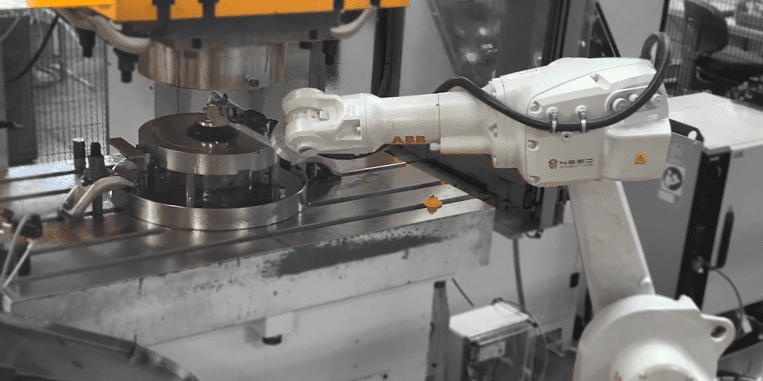

Handheld coordinate measuring machine

This handheld CMM is used to inspect parts, tools and assemblies and also allows us to carry out reverse engineering or compare parts to the CAD design with a high degree of accuracy, whatever the environment. This instrument is particularly useful for checks that require 3D measurement and is highly reliable. It can be used to accurately verify and digitise parts, thereby allowing production processes, quality assurance and reverse engineering to be improved.

Handheld probe coordinate measuring machine

This tool is used to make complex, high-precision measurements. Where vernier callipers offer limited control, a probe coordinate measuring machine is able to measure the most complex parts right on the work station. The instrument’s digital screen indicates the zones to be scanned in real time. An inspection report is then created and the scan data can be compared to 3D CAD files, for even more accurate analysis.

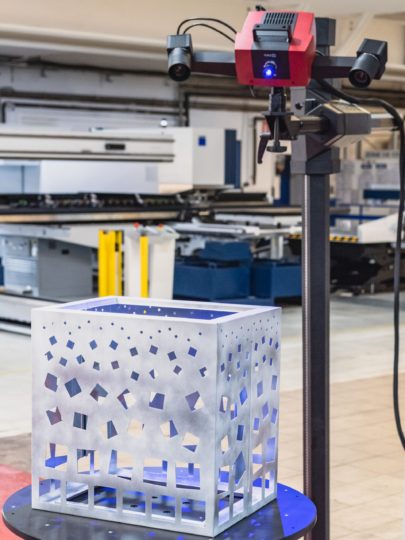

Handheld 3D scanner

This 3D scanner is specially designed to digitise difficult areas in 3D. This innovative device provides high-quality 3D scans, whatever the working environment. It is ideal for digitising narrow spaces and difficult-to-reach areas, such as deep grooves. This instrument can capture the 3D data relating to the shape of a part with great precision. It then produces detailed inspection reports with information such as distances, colour mapping, etc.

Reverse engineering allows CAD files to be produced from the 3D digitisation of a product. This technique is useful when the original drawing for a part is missing or non-existent.

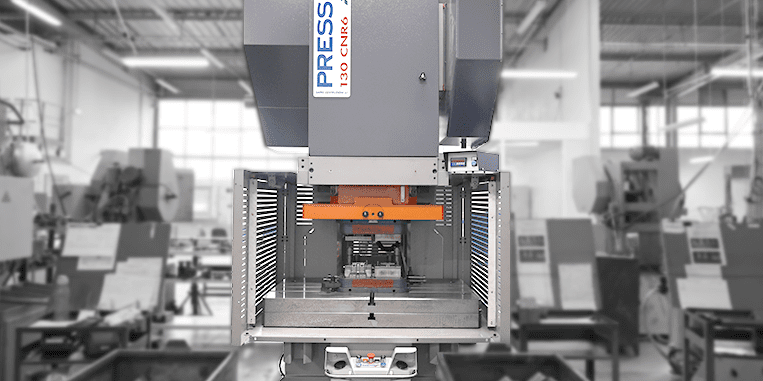

Regular replacements and additions to our machine pool

The TMA Group boasts a comprehensive pool of latest generation machines, which it maintains at the highest level thanks to an investment policy focused on automation and continual improvement. Quality and compliance with our customers’ requirements are thus guaranteed. The acquisition of automatic machinery and connected tools enables us to produce your metal parts with optimum cutting quality and precision.