Groupe TMA pioneered the field of laser cutting, and constantly invests in this state-of-the-art technology. Always on the lookout for technical progress and innovation, the machinery used by Groupe TMA offers the best performance of all laser cutting machines available on the market, enabling us to meet all your needs for parts cut out of steel, stainless steel and aluminium sheet.

Our expertise and skill in laser cutting

At Groupe TMA, our CO2 and fibre laser cutting units ensure the production of all your thin metal parts. These precision thermal cutting processes ensure tolerances of +/- 0.2 mm.

We adapt the cutting gas used in our laser machines to match your specifications. Oxygen is the standard gas; on request, we can use nitrogen to ensure that no calamine is produced on the cutting surface.

Groupe TMA shares all its expertise in 2D laser cutting and offers you made-to-measure solutions for manufacturing your metal parts.

Laser cutting – CO2 laser and fibre

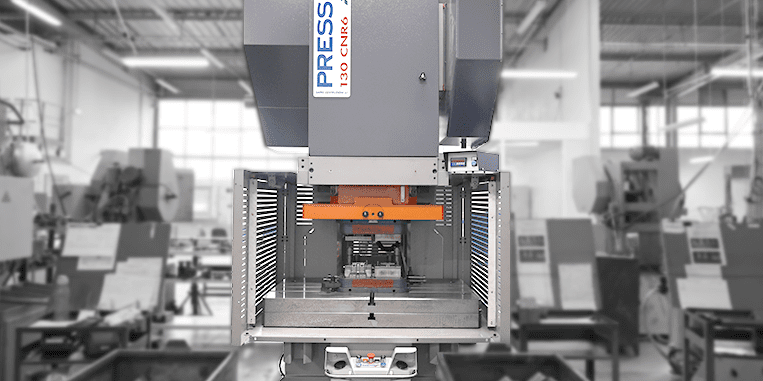

Groupe TMA specialises in the industrial cutting of metal sheet, putting its CO2 and latest-generation fibre laser equipment at your disposal. Our powerful Trumpf laser machines cut through steel, stainless steel and aluminium sheet up to 25 mm thick, depending on grade.

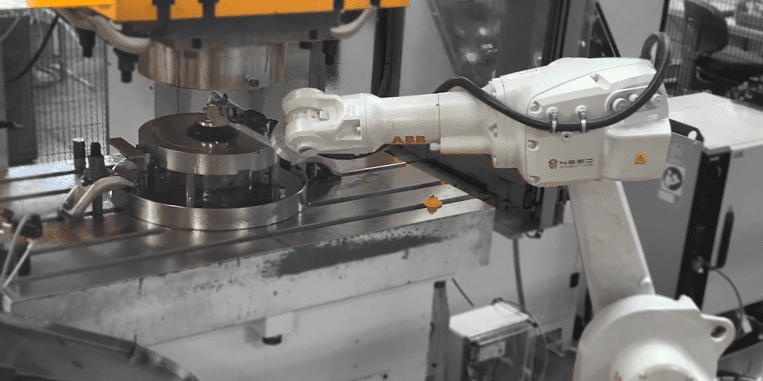

Whether it’s for a single part or a large run, our high-performance machines cut out your metal parts up to a maximum size of 2000 mm x 6000 mm. The automation of both our CO2 and fibre lasers and our loading and unloading facilities enable us to ensure continuous production, 24 hours a day, 7 days a week.

Our stock of steel, stainless steel and aluminium sheet for laser cutting

We have a permanent stock of 600 tonnes of material, comprising steel, stainless steel and aluminium sheet. The range of grades Groupe TMA offers covers hot- and cold-rolled steel, S235, S355 and high-tensile steel, pickled, galvanised, electro zinc-coated blackplate, and wear plates. All other grades are available to order.

We guarantee both the traceability of the materials we use and the compliance of all your parts. On request, we can supply a material certificate in accordance with NF EN 10204 – CCPU 3.1, the TÜV, US or any other technical inspection.

Laser finishing work and additional services

In addition to cutting, Groupe TMA also offers finishing work including vibratory finishing and shot-blasting. We also provide folding, chamfering, marking, machining, welding and surface treatment services for all your metal parts.